Stainless Steel Welded Pipe

Austenitic / Duplex Steel / Nickel Alloy / Cobalt AlloyASTM A213/A312 TP316/316L Stainless Steel Welded Pipe

IP-2-0003

Investing in Huxin Pipe, a factory with 36 years of pipe-making expertise, MTSCO has become a highly reliable manufacturer of welded pipes. This strategic partnership ensures the delivery of top-notch welded pipes backed by decades of industry experience.

The welded pipes from MTSCO come in a variety of sizes, with diameters reaching up to 3 meters, and hydrostatically tested pipes available in sizes up to 1.5 meters. This diversity in size caters to a wide range of industrial applications, providing flexibility to meet specific project requirements.

ASTM A213/A312 Pipe, TP316/316L Stainless Steel Welded Pipe

The welded pipes from MTSCO come in a variety of sizes, with diameters reaching up to 3 meters, and hydrostatically tested pipes available in sizes up to 1.5 meters. This diversity in size caters to a wide range of industrial applications, providing flexibility to meet specific project requirements.

| Grade | Standard | Outside Diameter | 219mm-3000mm |

| TP304 TP304L TP316 TP316L TP316Ti TP317L TP321 TP321H TP347 TP347H TP309S TP310S TP904L ... | ASTM-A312 ASTM-A358 ASTM-A790 EN10216 GOST ...... | Wall Thickness | 4mm-60mm |

| Length | ≤12m | ||

| Surface | Annealed Pickled/ Bright Annealed/ Polished | ||

| Inspection | Appearance/Size/PMI Inspection NDT:100%X-Ray/ET/UT/HT... Mechanical Testing Third Party Inspection | ||

| Certificates | ISO/PED/AD2000/TS | ||

| Package | End protection/ Woven bags/ Wooden cases |

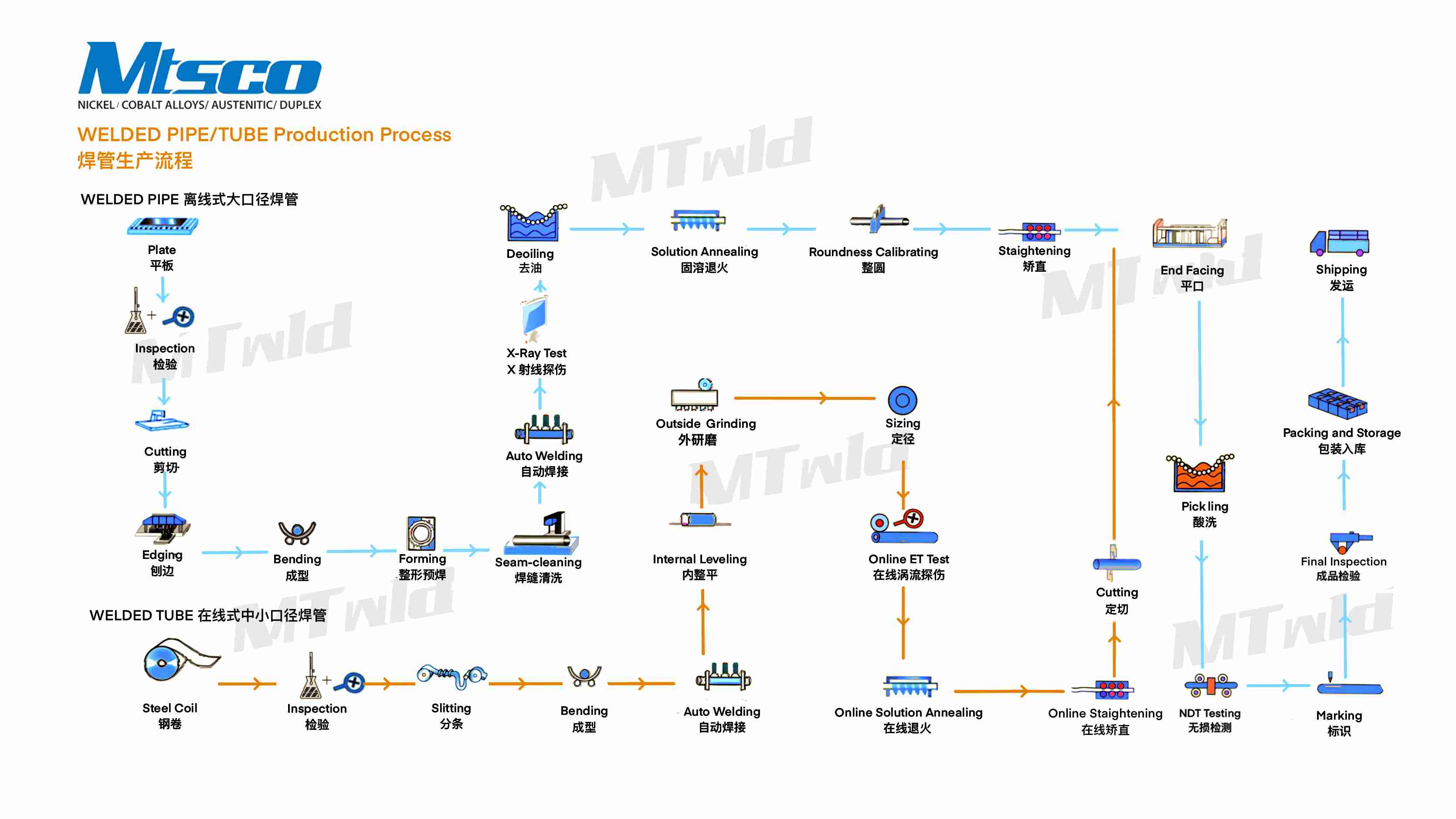

PROCESS:

With the advancement of technology and the development of material engineering, the processing and application technology of TP316/316L stainless steel is also advancing. For example, its corrosion and wear resistance can be further improved by surface treatment technology, while high-precision welding technology ensures that the strength and corrosion resistance of welded joints are comparable to those of the parent material.

In addition, with the improvement of environmental protection requirements and the pursuit of energy efficiency, TP316/316L stainless steel welded pipe is increasingly used in the development of new energy sources (such as ocean energy, hydrogen energy) and the construction of environmental protection facilities. These areas have higher requirements on the corrosion resistance and high pressure resistance of the material, TP316/316L responds to these challenges with its excellent performance, providing an effective solution.

Manufacturing Experience

Plant Area

Max Diameter of Welded Pipe

Annealing Furnace Length

What Grades Can We Provide?

Nickel Alloy

NI-MO: N10001,N10665,N10675...

NI-CR-MO: N10276,N06022,N06035,N06455,N06002...

NI-CR-MO-CU: N06030,N06200,N08031,N08825,N08020...

NICR-MO-W: N06230...

NICKEL: N02200,N02201...

NI-CU: N04400,N05500...

NI-CR-FE: N06600,N06601,N06690,N08800,N08810,N08811...

NI-CR-MO-NB: N06625,N07718...

Austenitic

304/L/H/N, 316/L/H/N/Ti, 321/H, 309/H, 310S, 347/H, 317/L, 904L...

Duplex Steel

31803, 32205, 32750, 32760...

Cobalt Alloy

Alloy 188/ UNS R30188, Alloy L-605/ UNS R30605, Alloy S-816, Alloy 6B, UMCo50, FSX-414, MP-159...

Feedback:

IP-2-0003-ASTM A213/A312 TP316/316L Stainless Steel Welded Pipe

Send Inquiry by feedback form learn more about product detail, price, etc.

Your email address will not be published. Required fields are marked *

FAQ

1. Can you provide samples?

2. Can we mark our logo on the product?

3. What is your packing?

4. What inspection will you do?

5. What certificates do you have?

6. What is your minimum order quantity(MOQ)?

7. How long is your delivery time?

8. What is your terms of payment?

Español

Español عربي

عربي Русский

Русский 한국인

한국인 Português

Português Türkçe

Türkçe Italiano

Italiano Français

Français German

German