Difference between stainless steel and nickel alloy heat exchanger tubes

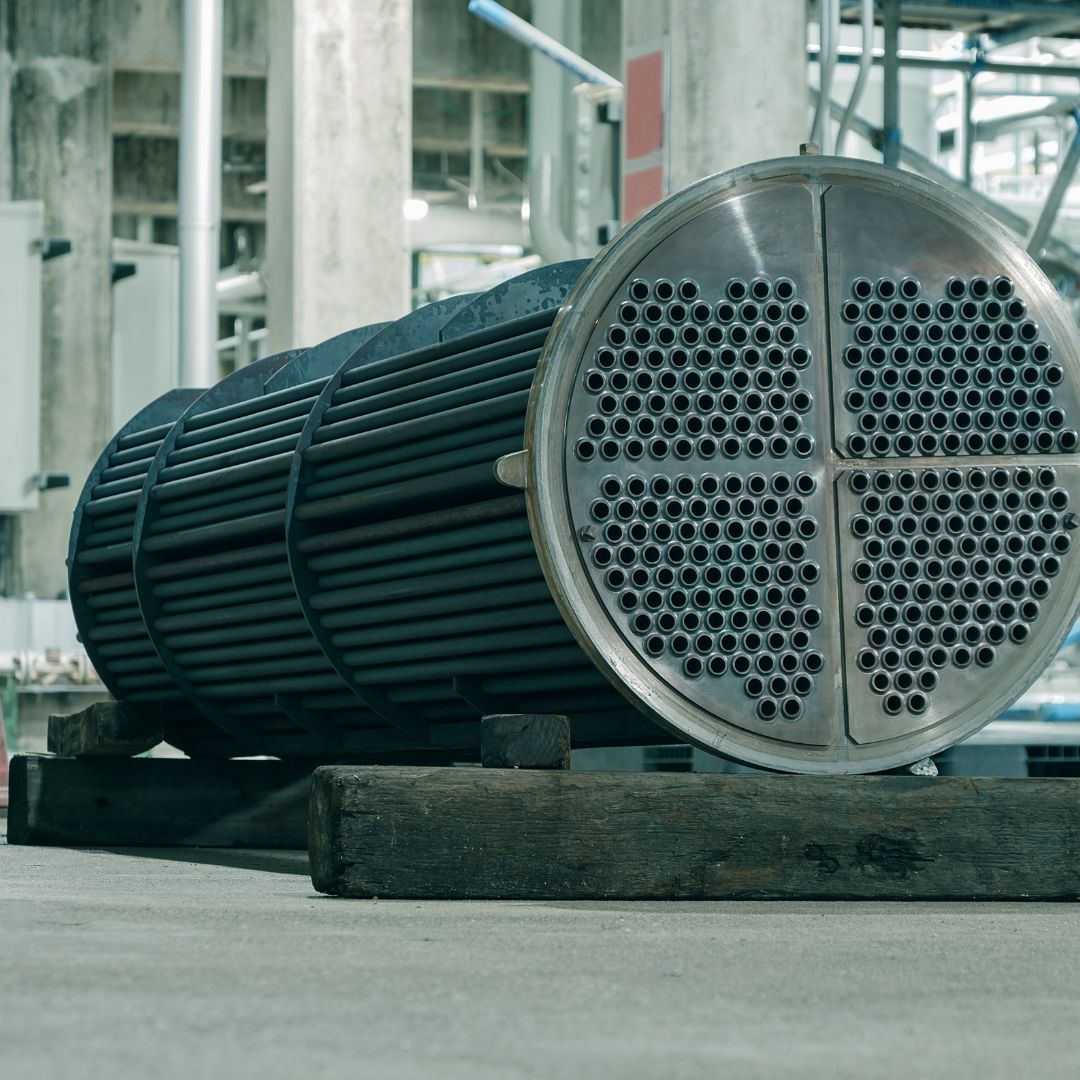

Stainless steel and nickel alloy heat exchanger tubes are common materials in heat exchange equipment, and they both have a wide range of applications in the field of heat exchange. Although they are both pipes used to conduct heat, there are obvious differences in material composition, performance characteristics and application areas.

Definition:

Stainless steel heat exchanger tube: Heat exchanger tube made of stainless steel, with good corrosion resistance, high temperature resistance and mechanical strength, widely used in chemical, petroleum, electric power, food and other industries.

Nickel alloy heat exchanger: Alloy heat exchanger made of nickel as the main component, with excellent corrosion resistance, high temperature resistance and oxidation resistance, suitable for extremely harsh application environments.

Differences:

Corrosion Resistance:

Stainless steel heat exchanger tubes: Corrosion resistance depends on the material and composition. Austenitic stainless steels (304, 316) are suitable for generally corrosive media, while high-alloyed stainless steels (310, 321) are suitable for more aggressive media.

Nickel alloy heat exchanger tubes: generally have higher corrosion resistance, especially in acidic, alkaline and high temperature environments. Nickel alloys such as Hastelloy (C-276, B-2) and Monel (400) exhibit excellent corrosion resistance in extremely harsh environments.

High Temperature Resistance:

Stainless steel heat exchanger tubes: High temperature resistance depends on the material and composition. Austenitic stainless steels can withstand temperatures up to 800°C, while high-temperature stainless steels (310, 321) can withstand even higher temperatures.

Nickel alloy heat exchanger tubes: Generally have a higher temperature resistance and can operate at temperatures above 1000°C. Nickel alloys such as Inconel 600 and Haynes 230 maintain good mechanical strength and oxidation resistance even at high temperatures.

Price:

Stainless steel heat exchanger tubes: relatively inexpensive and suitable for general applications.

Nickel alloy heat exchanger tubes: Higher price for special applications requiring high corrosion and temperature resistance.

Areas of application:

Stainless steel heat exchanger tubes: chemical, petroleum, power, food, pharmaceutical, paper, textile and other industries.

Nickel alloy heat exchanger tubes: Desalination, nuclear energy, aerospace, chemical, oil and gas industries.

We can clearly see the stainless steel and nickel alloy heat exchanger tube of their respective characteristics and areas of application. When choosing heat exchanger materials, comprehensive consideration should be made according to the specific application requirements, characteristics of the working environment and budget constraints to ensure the performance and economic benefits of the equipment.

Español

Español عربي

عربي Русский

Русский 한국인

한국인 Português

Português Türkçe

Türkçe Italiano

Italiano Français

Français German

German