The 20th century is a century of rapid development of modern science and technology, one of the important signs is the brilliant achievements of human beings in the field of aerospace. In the 21st century, aerospace has shown a broader development prospect, and high-level or ultra-high level aerospace activities are more frequent. The great achievements of aerospace industry are inseparable from the development and breakthrough of aerospace material technology

Superalloy: focus on military engine demand

1. Superalloy, produced for high temperature

Traditional steel will soften above 300 ℃ and cannot adapt to high temperature environment. In order to pursue higher energy conversion efficiency, the working temperature in the field of thermal engine power is higher and higher. Superalloy is bred and can work stably in the high temperature environment above 600 ℃, and the technology is constantly improving.

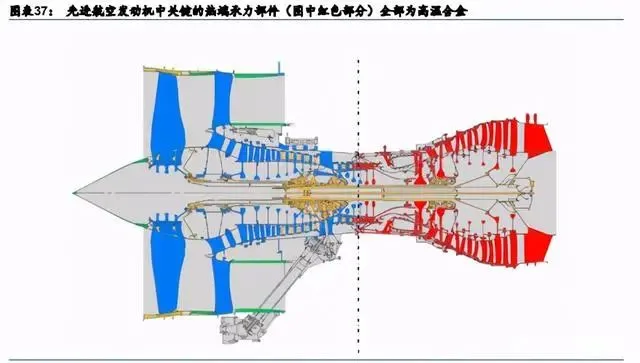

According to the main elements of the alloy, superalloys are divided into iron base, nickel base and cobalt base superalloys. In 2018, the output of nickel based superalloy, iron-based superalloy and cobalt based superalloy accounted for 80%, 14.3% and 5.7% respectively. Superalloy is the key material of aero-engine. It has been used in aero-engine since its birth, and is an important material for manufacturing aerospace engine. The performance level of engine largely depends on the performance level of superalloy materials. In modern aero-engine, the amount of superalloy materials accounts for 40% - 60% of the total weight of the engine. It is mainly used for four hot end components: combustion chamber, deflector, turbine blade and turbine disk. In addition, it is also used for gearbox, ring, afterburner and tail nozzle.

At present, China's superalloy industry is in a period of growth, and there is a broad space for the future development of industry chain enterprises. The number of China's superalloy production enterprises is limited, and the production level is far behind that of the United States, Russia and other state-owned enterprises, but in recent years, the production capacity and output value have improved significantly. Military superalloys are in the process of continuous upgrading, and R & D capability is the foundation of Superalloy enterprises.

2. Iron based superalloy

Iron based superalloy is used at low temperature (600 ~ 850 ℃), which is generally used in parts of engine with low working temperature, such as turbine disk, gearbox and shaft. However, iron-based superalloys have good mechanical properties at medium temperature, which are equivalent to or better than similar nickel based alloys. In addition, iron-based superalloys are cheap and easy to deform during hot working. So far, iron-based superalloys are still widely used in the field of medium temperature as turbine disks and blades.

3. Nickel base superalloy: deformation / casting / new alloy upgrading

Nickel base superalloy generally works under certain stress above 600 ℃. It not only has good high temperature oxidation resistance and corrosion resistance, but also has high temperature strength, creep strength and endurance strength, as well as good fatigue resistance. It is mainly used in the high temperature structural parts of aerospace field, such as the working blade, turbine disk, combustion chamber and so on. According to the manufacturing process, nickel base superalloys can be divided into variable alloy, cast superalloy and new type superalloy. Nickel base cast superalloy is mainly used for turbine guide vane in engine, and its working temperature can reach 1100 ℃ ° C above, can also be used for turbine blades, its temperature is lower than the corresponding guide vane 50-100 ° C。

ERAUM Alloy specializes in the production of corrosion-resistant nickel molybdenum alloy, aero-engine superalloy, nickel copper alloy for nuclear power, precision alloy, low expansion alloy and other new alloy products. The products strictly comply with the national standard, American /German /Japanese standard and other standards. The products are used in national defense, aerospace, transportation, equipment manufacturing, ship platform, oil, natural gas, chemical industry and other industries. Such as alloy 600 / 601 / 625 / 800 / 825 / C276 / 400 / 925 / GH3030, etc.

Through more than ten years of research and development, the production technology and efficiency of various materials have been greatly improved. The enterprise has passed the national quality management system certification of weapons and equipment, obtained more than 24 authorized patents, participated in the revision of 9 national standards and 3 industry standards. ERAUM has actively participated in the civil military integration project, provided high-temperature alloy materials for a PLA unit, provided high-quality special alloy materials for China ordnance industry group, and provided new low expansion alloy materials for China aviation industry. It has been successfully applied to the domestic large aircraft C919, replacing imports with domestic ones, breaking the foreign blockade monopoly and filling the domestic blank.

In addition to domestic supply, in recent years, through the cooperation of MTSCO, the export volume of nickel alloy has increased by 30% every year, and the quality and service are gradually recognized by the international market. In May, the 30 tons alloy 625 heat exchange tube just exported to the Netherlands, which passed the third-party inspection and won the strong praise of customers.

Choose ERAUM Alloy to give you more cost-effective products. We also have a more intuitive factory VR. Contact me to show you the factory online!

Español

Español عربي

عربي Русский

Русский 한국인

한국인 Português

Português Türkçe

Türkçe Italiano

Italiano Français

Français German

German