Nickel Alloy 825, a versatile, high-performance alloy, demonstrates excellent corrosion resistance in challenging environments. Composed of Iron, Chromium and Nickel, the addition of Molybdenum, Copper and Titanium allows it to remain stable under many extreme conditions. In particular, this alloy has excellent acid and alkali resistance and is able to resist corrosion in acidic and alkaline media. It is also resistant to chloride-induced stress corrosion cracking, as well as to attack by a wide range of organic and inorganic compounds.

Nickel Alloy 825 has a wide range of applications, including the following:

Aerospace: It can be used to manufacture engine parts, ducts, heat exchangers, nozzles, etc. for aircraft, and it can withstand high temperature, high pressure and high speed working conditions.

Marine engineering: it can be used to manufacture structural parts, pipes, valves, pumps, etc. of marine platforms, which can resist the erosion of seawater, salt spray, chloride and other corrosive media.

Chemical Processing: It can be used to manufacture chemical equipment such as reactors, tanks, heat transfer devices, distillation towers, condensers, etc. Nickel Alloy 825 is able to resist corrosion of various organic and inorganic acids, alkalis, salts and so on.

Environmental protection: it can be used to manufacture waste gas processor, waste water processor, solid waste processor of environmental protection equipment, etc. Nickel alloy 825 can reduce the emission of pollutants and improve the recycling rate of resources.

Nuclear energy utilization: it can be used in the manufacture of nuclear energy equipment such as nuclear fuel reprocessor, radioactive waste processor, nuclear reactor, etc. Nickel alloy 825 is able to resist the influence of radiation and ensure the safety and reliability of nuclear energy.

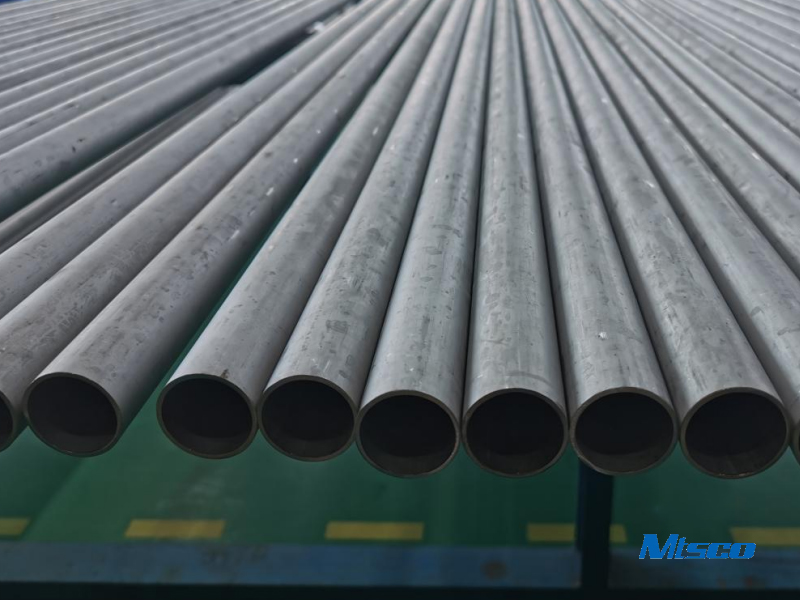

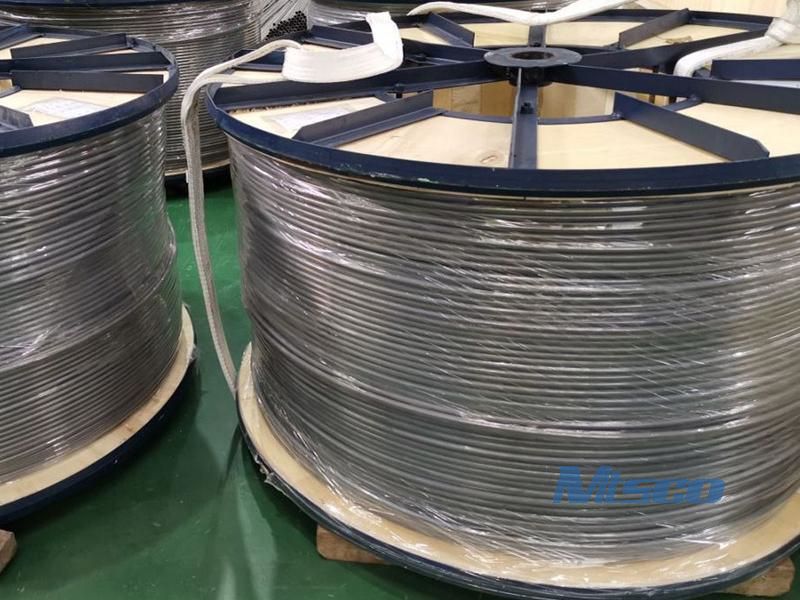

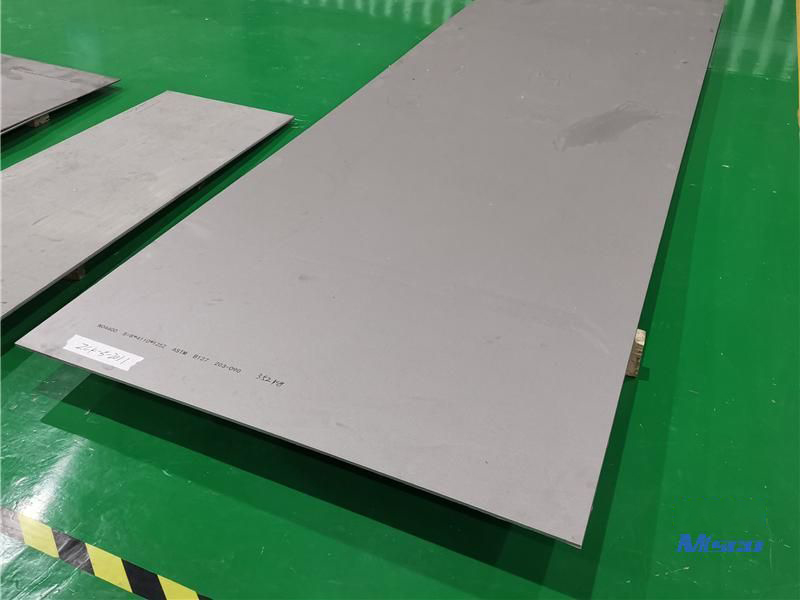

MTSCO offers a wide range of Nickel Alloy 825 products, including seamless pipe, welded pipe, fittings, flanges, coils and wire. With their consistently high quality and excellent corrosion resistance, our products meet the stringent requirements for high-performance materials in the industrial sector. Through advanced manufacturing techniques and strict quality control systems, we ensure that each product provides the strongest possible support for our customers' projects. Whether you need to withstand high pressure, high temperature environments, or face extremely corrosive chemical media, our Nickel Alloy 825 product line offers reliable solutions.

Español

Español عربي

عربي Русский

Русский 한국인

한국인 Português

Português Türkçe

Türkçe Italiano

Italiano Français

Français German

German