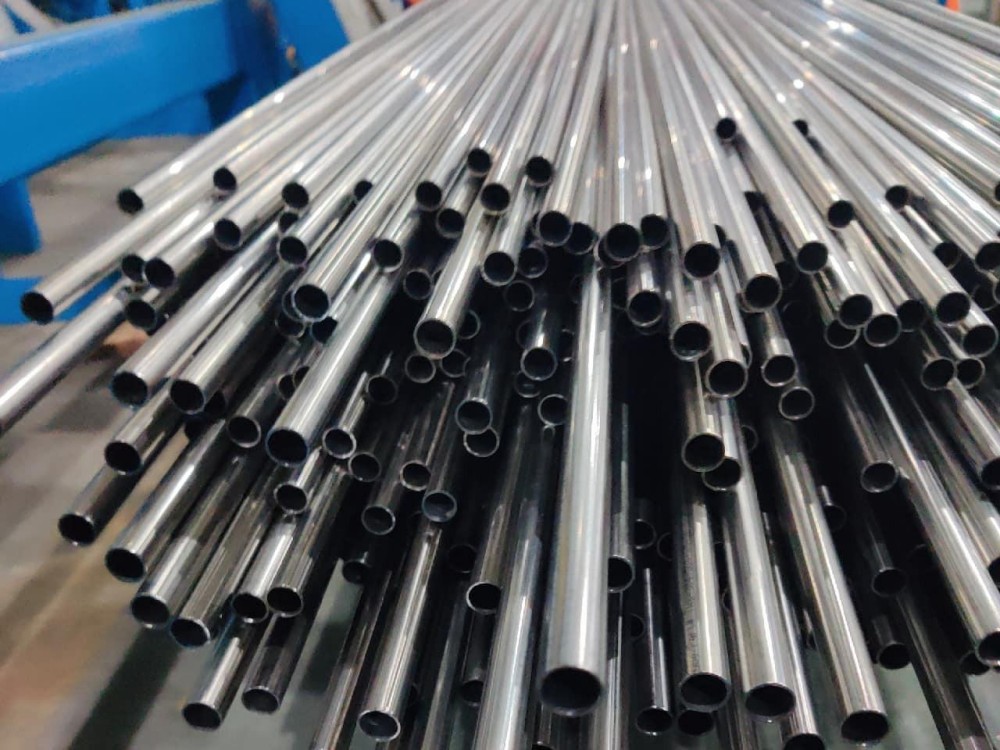

ASTM A789 duplex stainless steel pipes offer superior corrosion resistance and high strength, ideal for high-pressure and critical applications. Available in both seamless and welded forms, these pipes meet stringent industry standards for reliability in harsh environments.

The material types of ASTM A789 mainly include duplex stainless steels such as UNS S31803 (2205), S32205, and S32750 (2507). These materials combine the advantages of austenitic and ferritic structures, exhibiting higher strength and excellent corrosion resistance, especially in terms of resistance to pitting corrosion, crevice corrosion, and stress corrosion cracking.

In terms of chemical composition, ASTM A789 requires dual phase steel to have a chromium content range of 19% to 28%, a nickel content range of 4.5% to 8%, and a nitrogen content generally between 0.03% and 0.2%. This component design aims to optimize corrosion resistance and tensile strength, ensuring the reliability of pipelines in various environments.

Under the ASTM A789 standard, both duplex stainless steel seamless pipes and welded pipes demonstrate their unique advantages and adapt to different industrial needs.

Seamless pipes have high strength and excellent pressure resistance due to their manufacturing process without welded joints. The ASTM A789 standard strictly specifies the dimensional tolerances, chemical composition, and mechanical properties of seamless pipes, making them an ideal choice for high-pressure transportation and critical equipment applications, such as oil drilling pipelines and core pipelines in chemical equipment. During the production process, seamless pipes need to undergo cold or hot processing, followed by subsequent heat treatment to optimize grain structure and overall performance.

Welded pipes perform well in medium and low pressure applications due to their lower manufacturing costs and flexible length design. According to ASTM A789 requirements, the welds of welded pipes must undergo heat treatment to relieve stress and ensure consistency between the weld area and the properties of the base material. Welded pipes are particularly suitable for use in heat exchangers, tank connection pipelines, and seawater treatment equipment, meeting industrial needs and reducing overall procurement costs.

Dual phase steel is favored in multiple industrial fields due to its excellent mechanical properties and corrosion resistance, especially performing well in harsh environments. The ASTM A789 standard provides important specifications for seamless and welded pipes of duplex steel, ensuring that their quality and performance meet the relevant application requirements.

Español

Español عربي

عربي Русский

Русский 한국인

한국인 Português

Português Türkçe

Türkçe Italiano

Italiano Français

Français German

German